Robotics company Rethink Robotics has made a name for itself with the Baxter industrial robot, which is designed specifically to work on conveyor lines. It adapts and learns, and is faster than any human.

Sawyer is a new generation of robot on the same platform as Baxter. And it has the same screen with a friendly face.

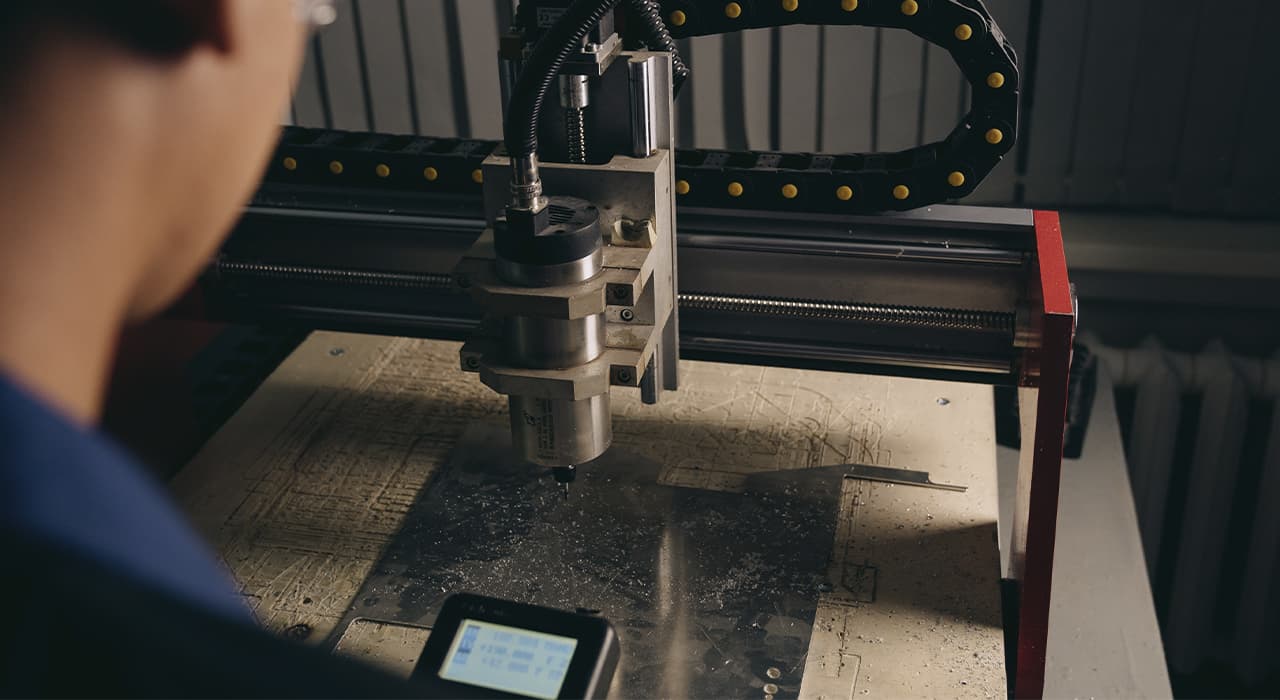

It is a robot with a manipulator arm, designed for assembling electronics and other devices requiring high-precision manipulation.

Sawyer borrowed from its predecessor a system of built-in sensors and a self-learning mechanism. It uses the same Intera software platform, so it can dynamically adjust to the necessary requirements, just as humans do. The software is updated every four months, so the robot constantly has new abilities.

According to the manufacturer, Baxter and Sawyer together can cover 90 percent of all jobs that cannot be automated by existing methods.

The Sawyer weighs 19 kg and has a payload of up to 4 kg. It has “seven degrees of freedom,” the Baxter says (it’s not quite clear what degrees of freedom they mean) and has a reach of one meter.

The Sawyer’s special feature is the high precision of movement of the manipulator, which was made possible thanks to the built-in “head” camera with illumination and a system of pattern recognition. The software recognizes various objects and can, for example, scan barcodes.

The Sawyer retails for $29,000 (the Baxter cost $22,000). Such a machine can be bought not only by industrial enterprises, but also by rich citizens. For example, to have it cook food and do other household chores. For example, the mechanical arm is able to assemble furniture, iron the cat, and do other important things.