Simply put, a robot (from Czech, robota, servitude) is a cybernetic system that can perform operations related to human physical and mental activities. A robot includes a programmable control system that controls the mechanical design and also links the robot to the external environment (equipment and the user).

Finally, in a broader sense, a modern robot is a mechanism that performs programmed actions, which perceives the world around it using sensors (sensors, microphones, cameras), builds behavior patterns to execute a specific program, and is able to affect the physical world in one way or another.

A brief history of robotics

Over the past 100 years, robots have not just evolved, they have become part of our everyday lives. The word “robot” came into use after Karl Capek’s play about artificial human beings was published in 1920. And this is very symbolic, since the “roaring” twenties were a period of economic boom and new discoveries in science and technology.

In the decades that followed, there were outstanding discoveries in a variety of disciplines – cybernetics, mechatronics, computer science, electronics, mechanics, and it is these that robotics relies on. Around the 1930s, the first androids, which could move and utter simple phrases, appeared.

The first programmable mechanisms with manipulators were designed in the 1930s in the United States. The impetus came from Henry Ford’s work on an automated production line. At the turn of the 1930s and 40s, automatic lines for processing bearing parts appeared in the USSR, and in the late 1940s, the world’s first integrated production of pistons for tractor engines with automation of all processes – from loading raw materials to packaging the finished product – was created.

Three generations of robots

The first generation robots, mastered by industry in the 1960s, operated according to a rigid program, could not adapt to changing production and environmental conditions, and required an orderly arrangement of oriented parts in a storage bin at the input. Some of the first industrial robots, Versatran and Unimatte, are still in operation today, having passed the 100,000-hour operating time threshold.

Second-generation robots work according to a flexible program and are used for complex manufacturing tasks, such as assembling precision products. High-precision – high-precision or created with high-precision parameters. Such robots have a more developed sensor apparatus, which provides the “situation-action” principle and is able to choose the optimal algorithm of functioning depending on the course of the production process.

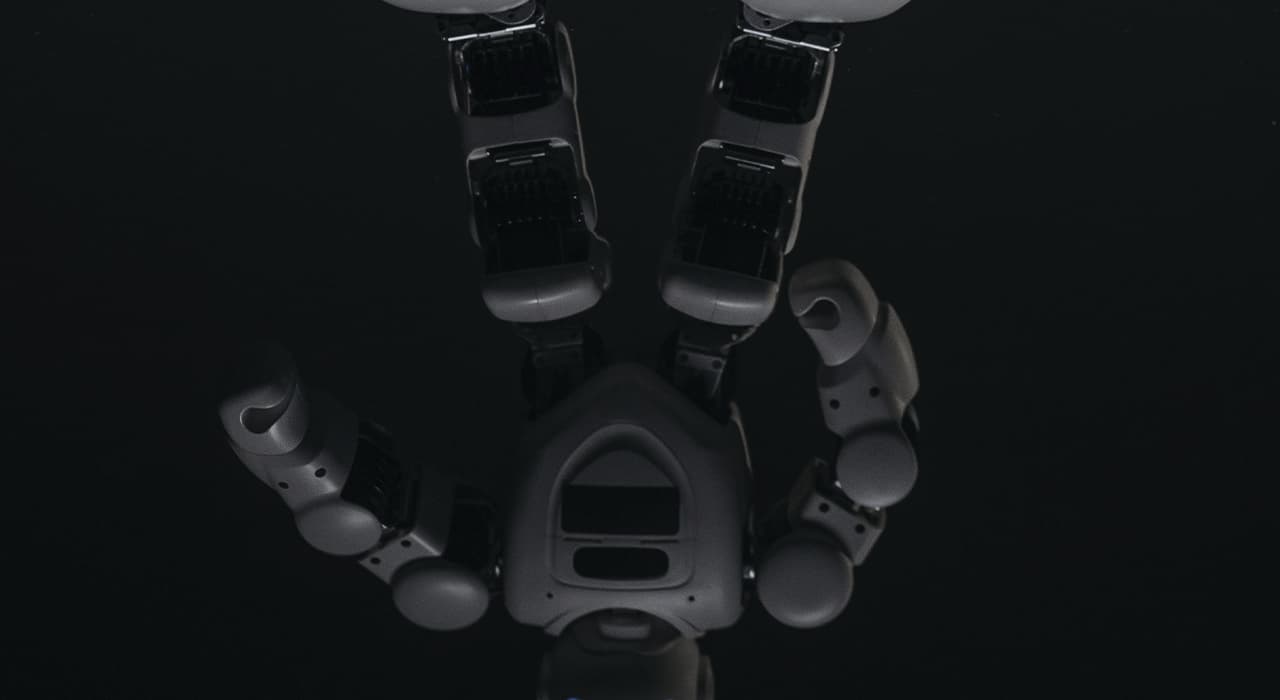

The third generation robots are already integral or intelligent systems equipped with the latest adaptation tools. They have the ability to self-learn and recognize images, which is an important element of artificial intelligence. With the development of AI, robots are able to simulate the external environment, analyze the production environment, make decisions and plan their own actions.

Classifications of robots

Depending on their general application area, robots can be divided into industrial and service robots. Today, there are more industrial robots in the world, but the service robot niche is growing at a tremendous rate.